Syngasfermentation at Elevated Pressure

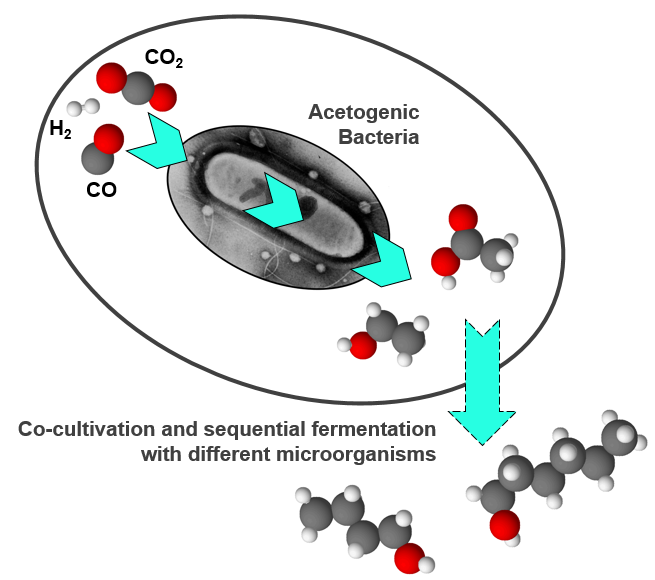

A promising possibility to utilize synthesis gas is Syngasfermentation: a process for the biotechnological production of fuels and chemicals by converting a gas mixture of hydrogen (H2), carbon monoxide (CO) and carbon dioxide (CO2) using anaerobic, acetogenic microorganisms. The substrate gas can be produced by biomass/waste gasification or electrolysis. Industrial waste gases are also possible substrate sources. This biological gas-to-liquids (GTL) process represents a sustainable platform for reducing dependence on fossil raw materials and reduces CO2 emissions.

A significant limitation in synthesis gas fermentation is the low solubility of some gases. Carbon monoxide and hydrogen are only sparingly soluble in water, which limits the availability of the substrate for the microorganisms. The strategy of IKFT for high substrate availability during the fermentation is increasing the gas solubility by employing elevated process pressure. Therefore, the influence of pressure on synthesis gas fermentation is investigated in a newly constructed laboratory plant. In the stirred tank reactor with a working volume of 2.5 L H2/CO2- and H2/CO/CO2-fermentations were initially carried out in semi-batch operation (continuous gas supply) with a pressure up to 7 bar.

With regard to a technical realization, a continuous operating mode is advantageous. Thus, the work concentrated on the modification of the lab plant and an optimization of the process control. This now enables stable pressurized fermentations with run times of > 1400 h.

A Bachelor/master thesis on the subject of gas fermentation at elevated pressure is possible.

Contact: lukas.perret∂kit.edu or nikolaos.boukis∂kit.edu

Power to X

An alternative source for syngas is electrolysis. In a conventional H2O electrolysis process, a chemical reaction is forced by the use of electricity and generates H2 from water. The same applies to CO2 electrolysis, where CO2 is used to form carbon monoxide. This type of gas generation is a future option if there is excess electricity from renewable energy sources, e.g., from solar or wind power plants. The gas mixture can be converted into valuable platform chemicals such as butanol and hexanol by using suitable microorganisms. This process chain is part of the BMBF-funded Kopernikus project P2X (https://www.kopernikus-projekte.de/en/projects/power2x).

The second funding phase of P2X has started in autumn 2019.

A promising possibility to utilize synthesis gas is Syngasfermentation: a process for the biotechnological production of fuels and chemicals by converting a gas mixture of hydrogen (H2), carbon monoxide (CO) and carbon dioxide (CO2) using anaerobic, acetogenic microorganisms. The substrate gas can be produced by biomass/waste gasification or electrolysis. Industrial waste gases are also possible substrate sources. This biological gas-to-liquids (GTL) process represents a sustainable platform for reducing dependence on fossil raw materials and reduces CO2 emissions.

A promising possibility to utilize synthesis gas is Syngasfermentation: a process for the biotechnological production of fuels and chemicals by converting a gas mixture of hydrogen (H2), carbon monoxide (CO) and carbon dioxide (CO2) using anaerobic, acetogenic microorganisms. The substrate gas can be produced by biomass/waste gasification or electrolysis. Industrial waste gases are also possible substrate sources. This biological gas-to-liquids (GTL) process represents a sustainable platform for reducing dependence on fossil raw materials and reduces CO2 emissions.