In-Situ Reaction Measurement Technique

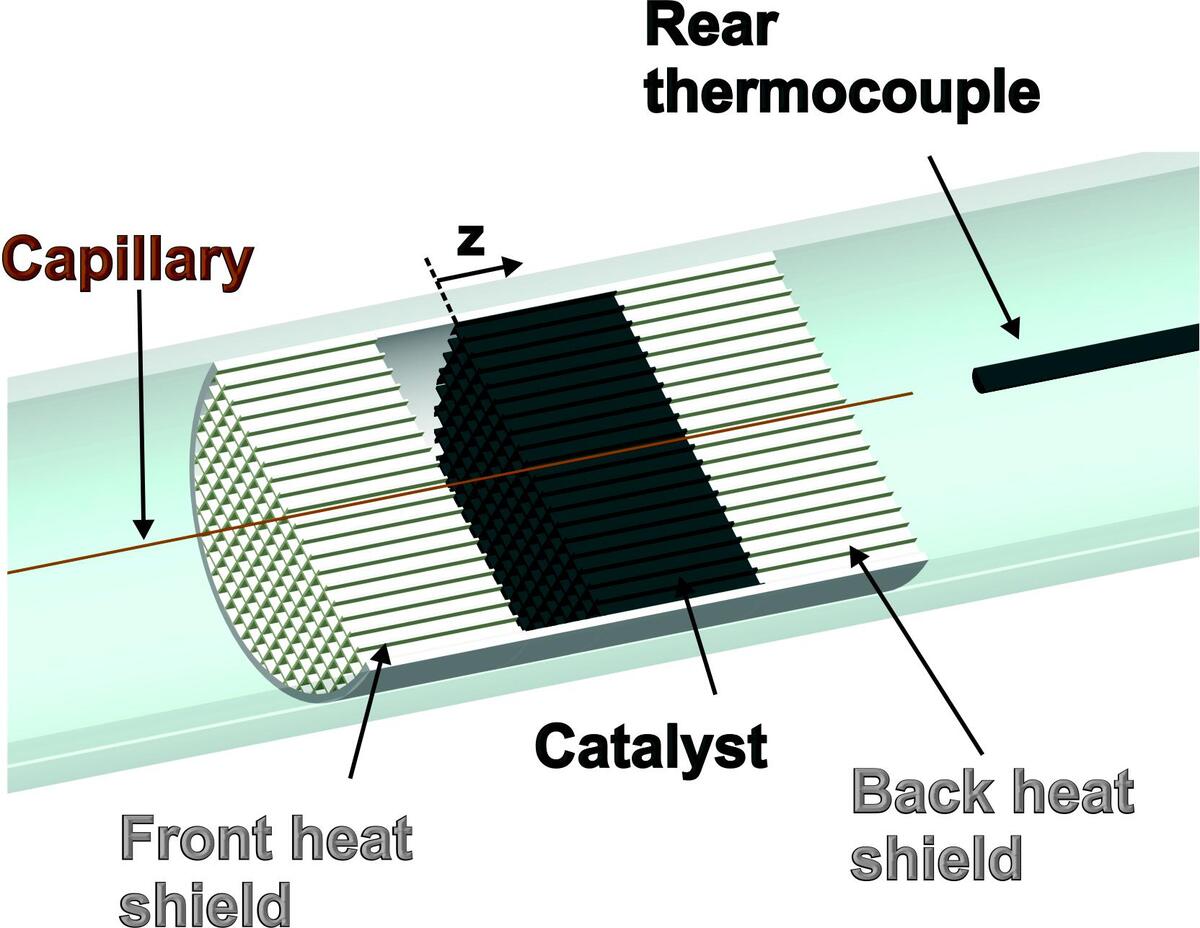

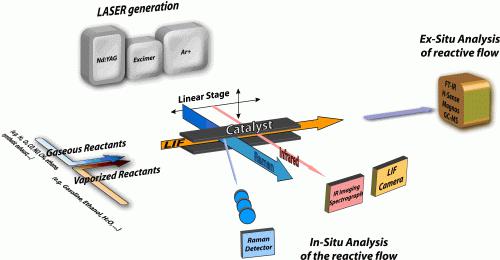

Catalysis has recently been extensively discussed not only for the reduction of pollutant emissions in automobiles such as nitrogen oxides but also for the synthesis of fuels, basic chemicals, and hydrogen from sources like natural gas and bio-mass. Focusing on the field of heterogeneous catalysis, we examine various catalytic systems, mainly monolithic honeycombs, in high-temperature catalysis. The investigations allow us to validate and improve existing mechanisms or to develop new ones. Furthermore, the gained knowledge can be used in catalyst as well as reactor design, and optimization of operating conditions. Our group utilizes a combination of in-situ and ex-situ measuring techniques. Ex-situ measurements using FT-infrared spectroscopy, mass spectrometry, and a paramagnetic oxygen analyzer are applied for initial screening of processes and the study of highly complex processes such as the catalytic partial oxidation (CPOX) of logistic fuels, e.g. kerosene, gasoline. For profound investigations, two different approaches to in-situ techniques are available. On the one hand, we use an in-situ probe technique – SpaciPro (Spacial Profiles) – with which we take gas samples and measure the gas-phase temperature as well as the surface temperature by inserting a capillary into a selected channel of a catalytic monolith. With this technique, axial concentration and temperature profiles are detectable. Investigated systems were e.g. CPOX of ethanol and methane on Rh/Al2O3. On the other hand, we operate the laboratory for CATalysis at High Temperature Laser ENvironment (CATHLEN), which consists of a non-invasive in-situ experiment utilizing laser induced fluorescence (LIF) as well as Raman spectroscopy to obtain 2D concentration profiles in a catalytic flow cell. This technique was deployed e.g. for the oxidation of NO on Pt/Al2O3.

We work in close collaboration with the Chemical Technology (Prof. Deutschmann) at the Institute of Chemical Technology and Polymer Chemistry.